Error-proof your discrete assembly process and equip semi-skilled operators to carry out complex operations and build high-quality parts.

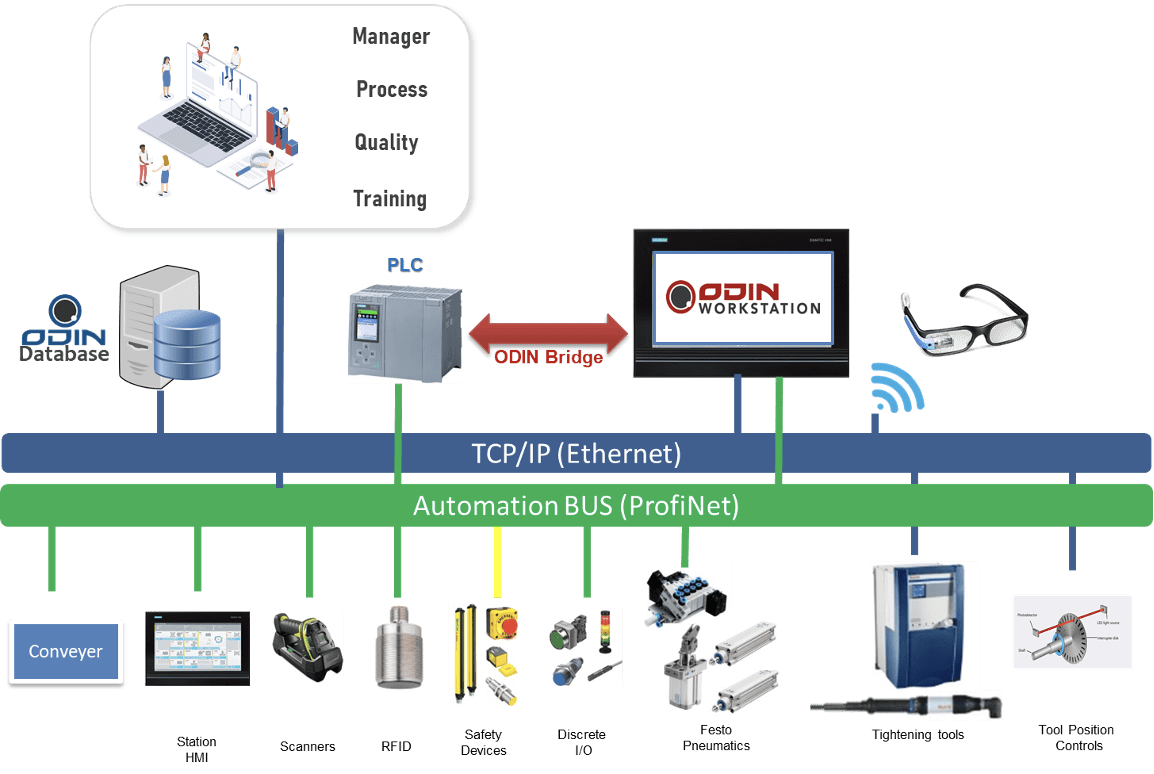

ODIN Workstation is a digital infrastructure solution with core features that include:

- AI-assisted operator guidance

- quality assurance

- direct device integration

- production planning, and

- advanced analytics.

Made for manufacturers of all sizes

Designed for any size manufacturer, ODIN Workstation allows you to start with a single station and grow to large-scale enterprise solutions.

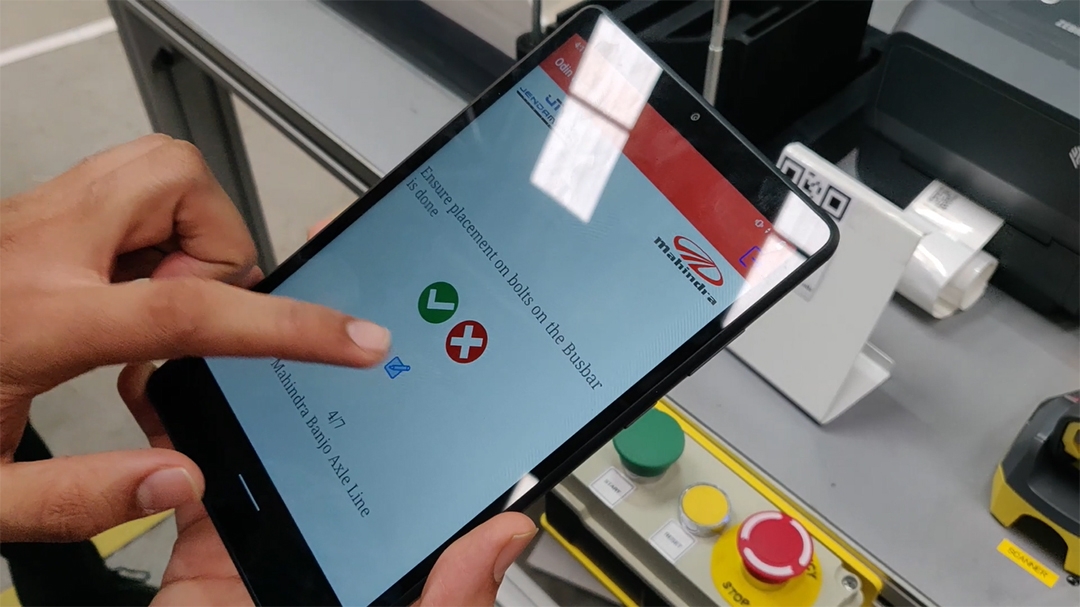

Error-proof your manual assembly with AI-assisted operator guidance

Assemble right, assemble more, assemble faster with visual work instructions.

Use the power of AI computer vision to guide the operator through an accurate assembly process.

Collect end-of-line quality data in one place

Digitise your end-of-line Quality Assurance check sheet, including the uploading of corroborating images.

Empower your process engineers and production managers

No coding makes line planning easy – simple to set up and reconfigure any time.

Benefit from built-in quality assurance and traceability

Record and confirm every process step, including failed, skipped, and reworked steps.

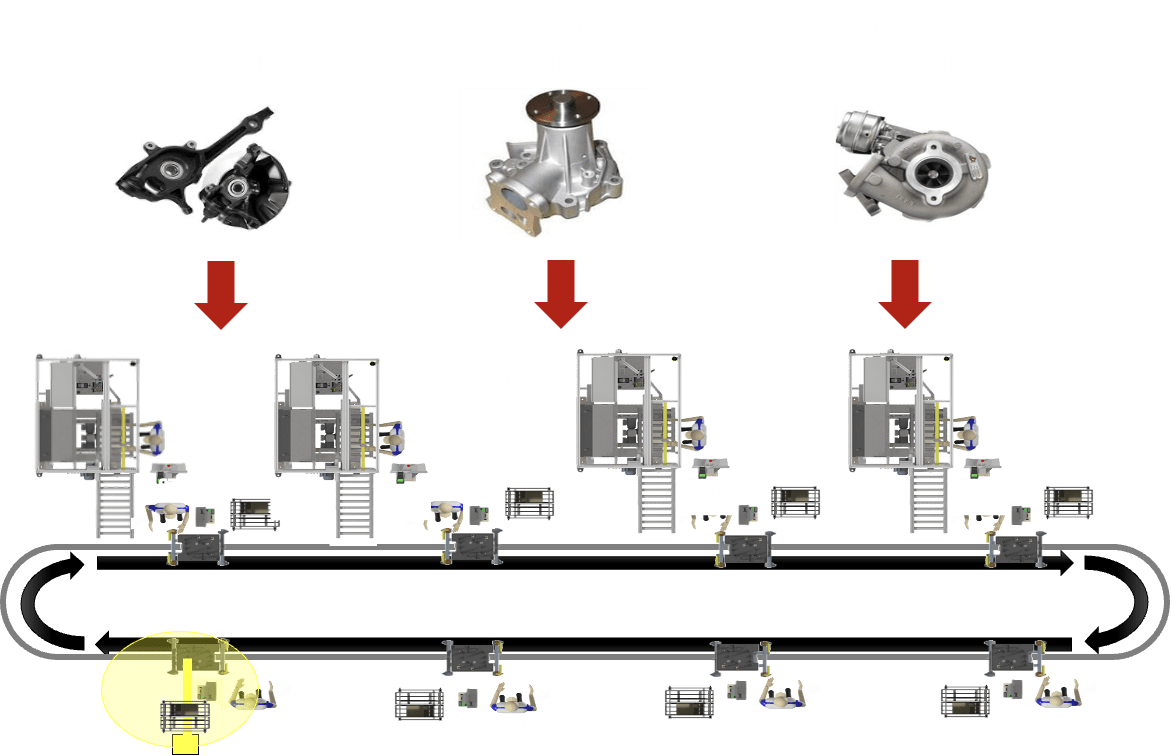

Build any variant in any sequence

A dynamic build sequence allows you to switch variants and build multiple products on the same assembly line.

Manage your risk and reduce costs

Dedicated rework and disassembly functions lead to lower scrap rates and improved overall product quality

Simplify the integration of your production line equipment

One integrated platform connects manual, semi-automatic and automatic station equipment – with deep hardware integration.

Access analytics that matter

Get relevant, real-time data straight from your production line. Our solution automatically collects, analyses and presents the data, which means your engineers can devote their time to solving the problem instead of trying to find it.

HOW WORKSTATION HAS HELPED OUR CUSTOMERS

Explore our case studies library for all the success stories and how we solved our customers’ respective challenges with an ODIN solution

LET US CALL YOU

Leave your details here and our solutions engineer will be in contact to answer your queries or set up a demo.

"*" indicates required fields

Intuitive animated operator guidance instructions

Intuitive animated operator guidance instructions