Monitor the health of your critical equipment to facilitate preventative maintenance and avoid unplanned machine downtime.

Real-time alerts and insights on the health of your assets

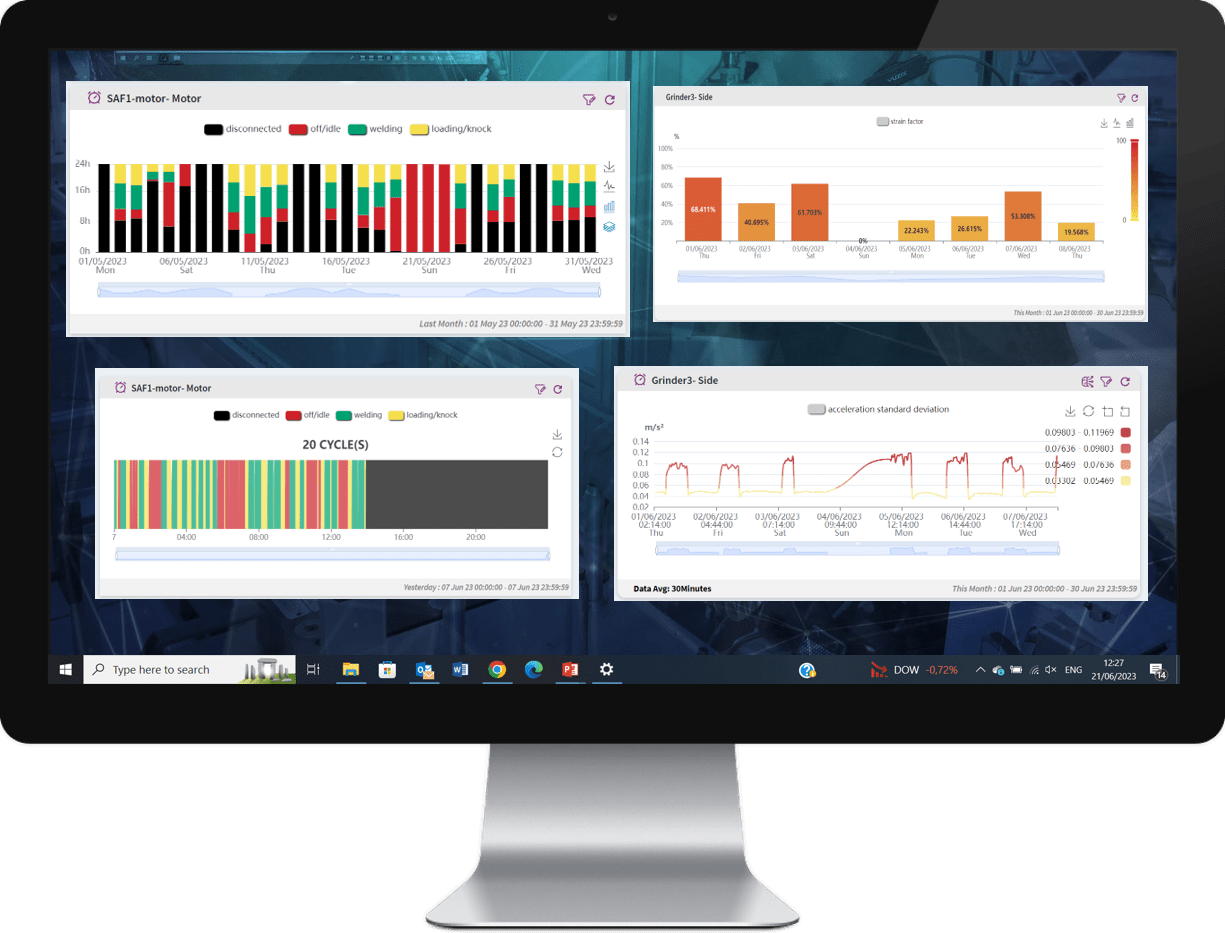

Access to analytics

Access the vibration analytics by onboarding your sensor to the ODIN Checkpoint dashboard.

Track asset usage and operation state, monitor machine cycles and output, and use the data to predict potential failures and schedule just-in-time preventative maintenance.

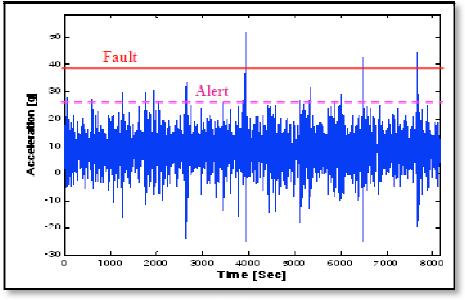

Automatic alerts

When the sensor detects an anomaly, the system automatically raises an alert and assigns a technician to attend to the task.

Custom alerts and notifications

Never miss out on crucial metrics with custom alerts and notifications based on your data.

Immediately discover harmful operating conditions by configuring alerts for your data. Notifications are sent to the specified parties for any of the widgets you created in your personal or organisation-wide dashboards.

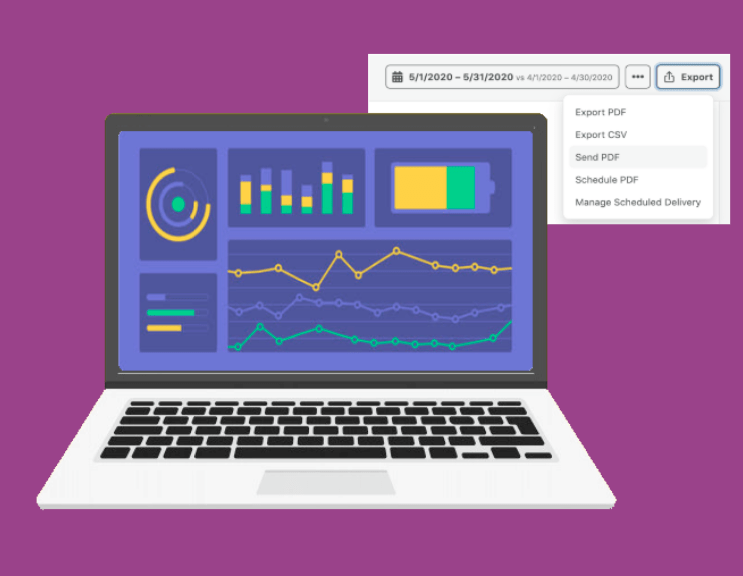

All your key data at a glance

Investigate the patterns in vibration signals for your asset, enabling you to monitor its overall condition in comparison to established standards or your own maintenance history.

Share your private dashboards across your organisation or with selected individuals. Export dashboards according to a schedule, straight to your email or for use in other applications or services.

Easily onboard your sensor to the ODIN platform

Onboard a sensor for your organisation using our mobile app. Then simply scan your ODIN QR code to associate a sensor with your asset and begin visualising your vibration data in real time.

HOW RAVEN+CHECKPOINT HAS HELPED OUR CUSTOMERS

Explore our case studies library for all the success stories and how we solved our customers’ respective challenges with an ODIN solution

LET US CALL YOU

Leave your details here and our solutions engineer will be in contact to answer your queries or set up a demo.

"*" indicates required fields