$12bn turnover, 250 000 employees, 150+ locations, in over 100+ countries

$12bn turnover, 250 000 employees, 150+ locations, in over 100+ countries

Mahindra needed an innovative way to train operators on new variants, while performing this training ‘live’ on-the-line – which caused unnecessary and increased costs as a result of the frequently experienced production delays, inefficiencies and rework

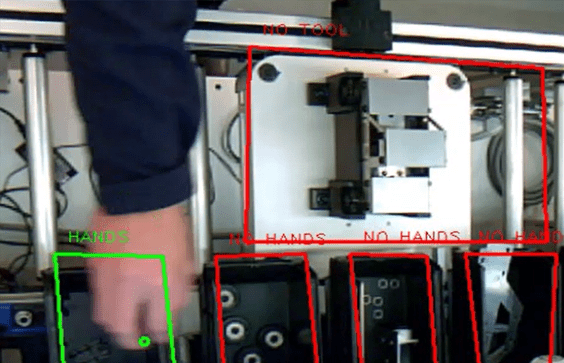

By implementing ODIN Workstation throughout the entire line.