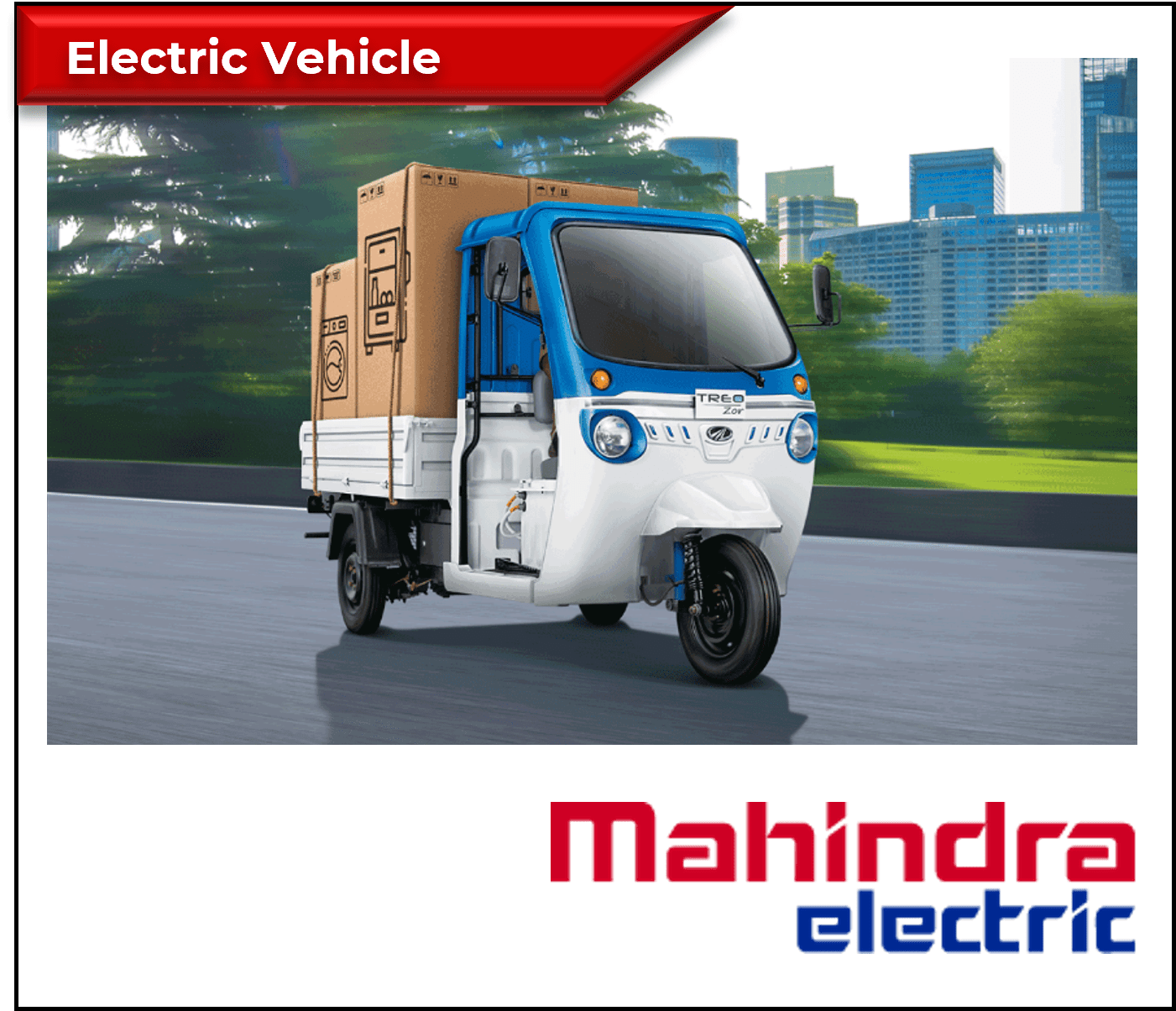

About The Customer

$12 billion turnover | 250 000 employees | 150+ locations in over 100 countries

The Challenge

Mahindra needed an innovative way to train operators on new variants, while performing this training ‘live’ on-the-line – which caused unnecessary and increased costs as a result of the frequently experienced production delays, inefficiencies and rework.

How We Did It

By implementing ODIN Workstation throughout the entire line.

Final Results

- Visual & text-based work instructions, assisting even entry-level operators

- Enhanced operator guidance for existing and new products

- Increased training speed for new operators

- Fewer defects

- Less scrap

- Less time to change processes and operations to improve assembly/manufacturing sequences

Other Benefits

- Operators avoiding incorrect assembly, even on complex variants through visual, dynamic work instructions

- Additional failsafe’s are part of the default system features, aiding operators in ensuring that the correct parts are always used and are correctly positioned

- Live ANDON displays current production targets, line progress and status above the production line, ensuring full line transparency

- Easy-to-use, no code interface facilitates easy continuous improvement adjustments